Had to re-glue aileron spar. Most supperficial pine was fast growing and very weak/unstable.

Had to re-glue aileron spar. Most supperficial pine was fast growing and very weak/unstable.

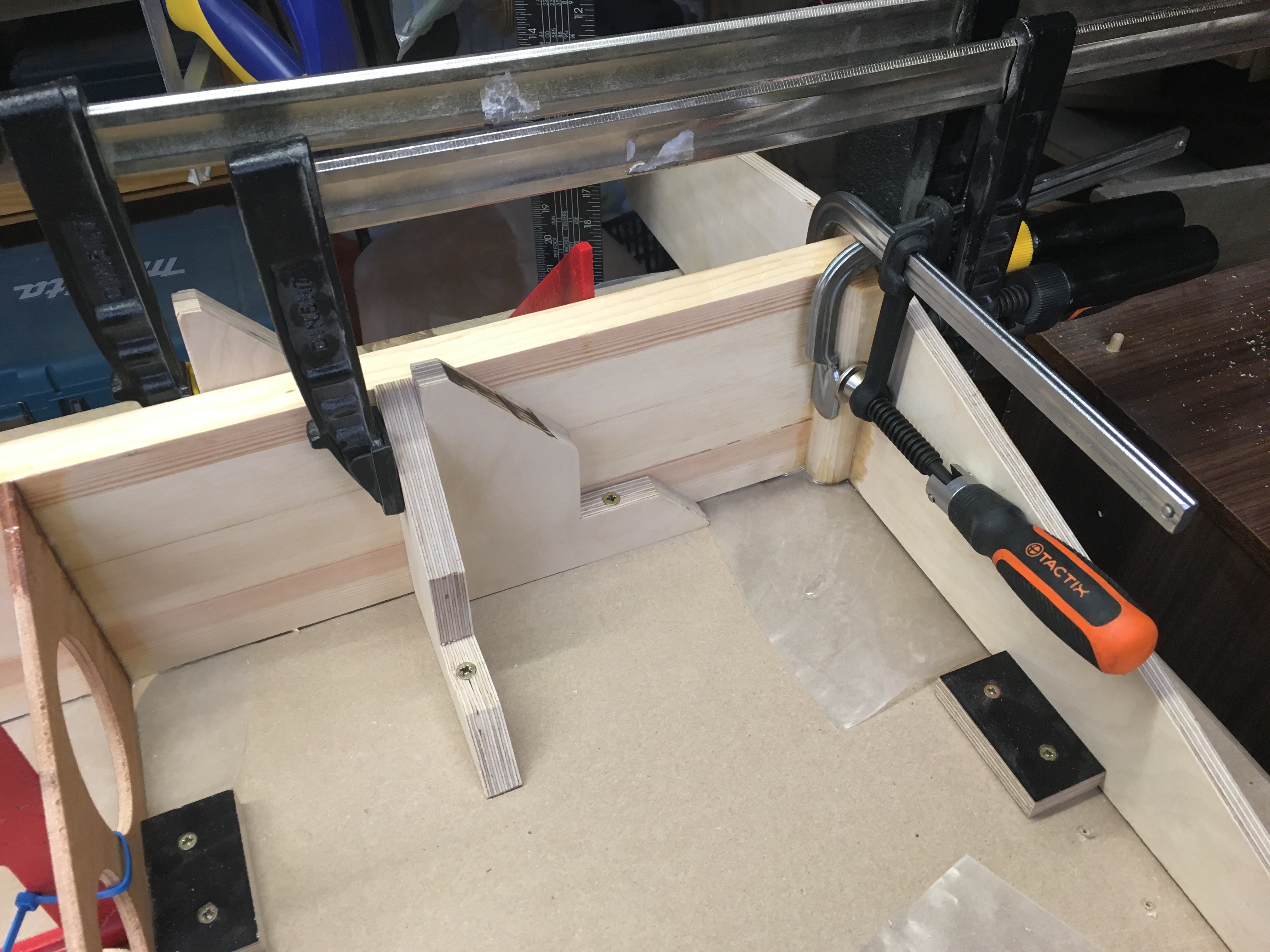

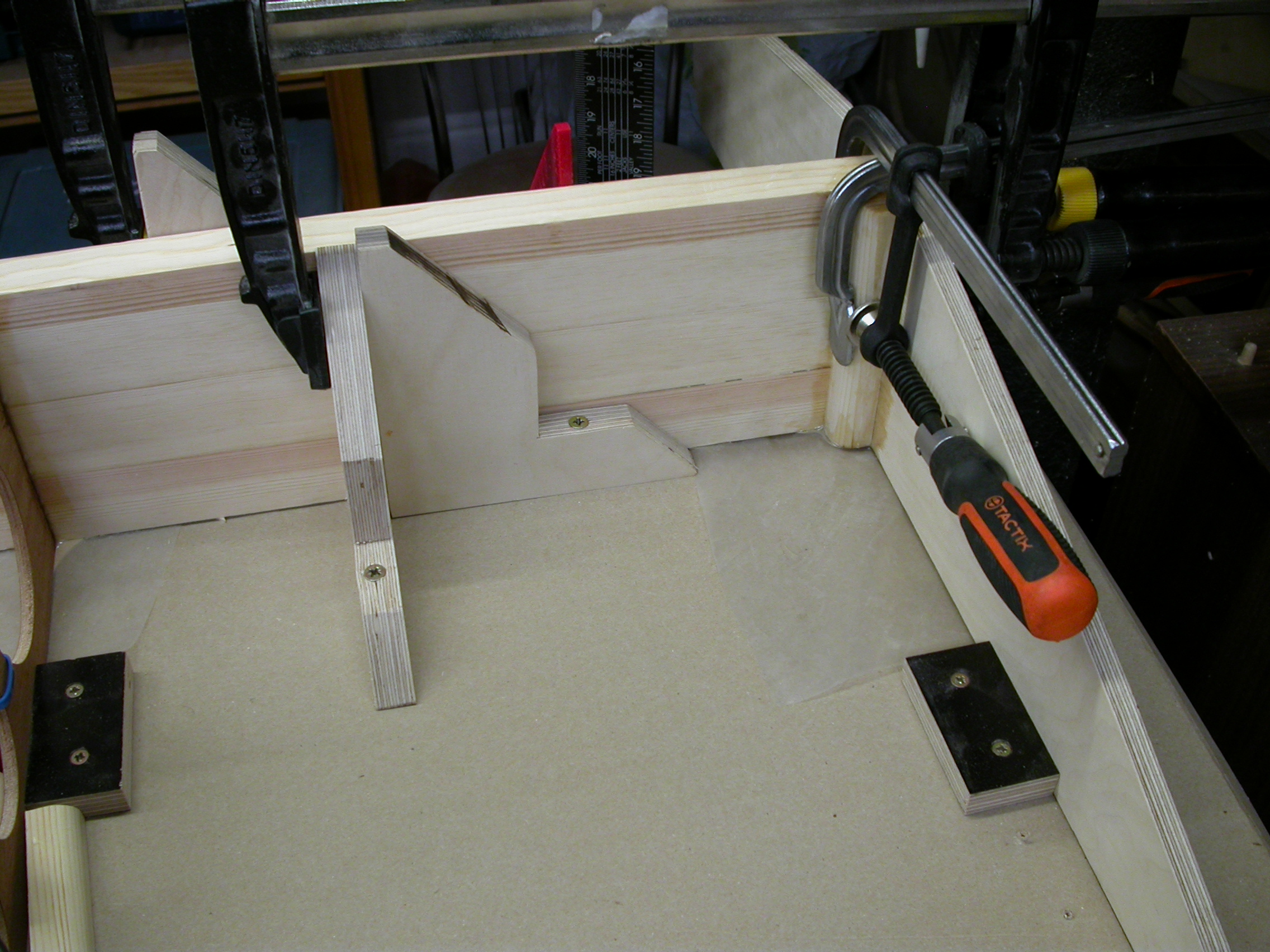

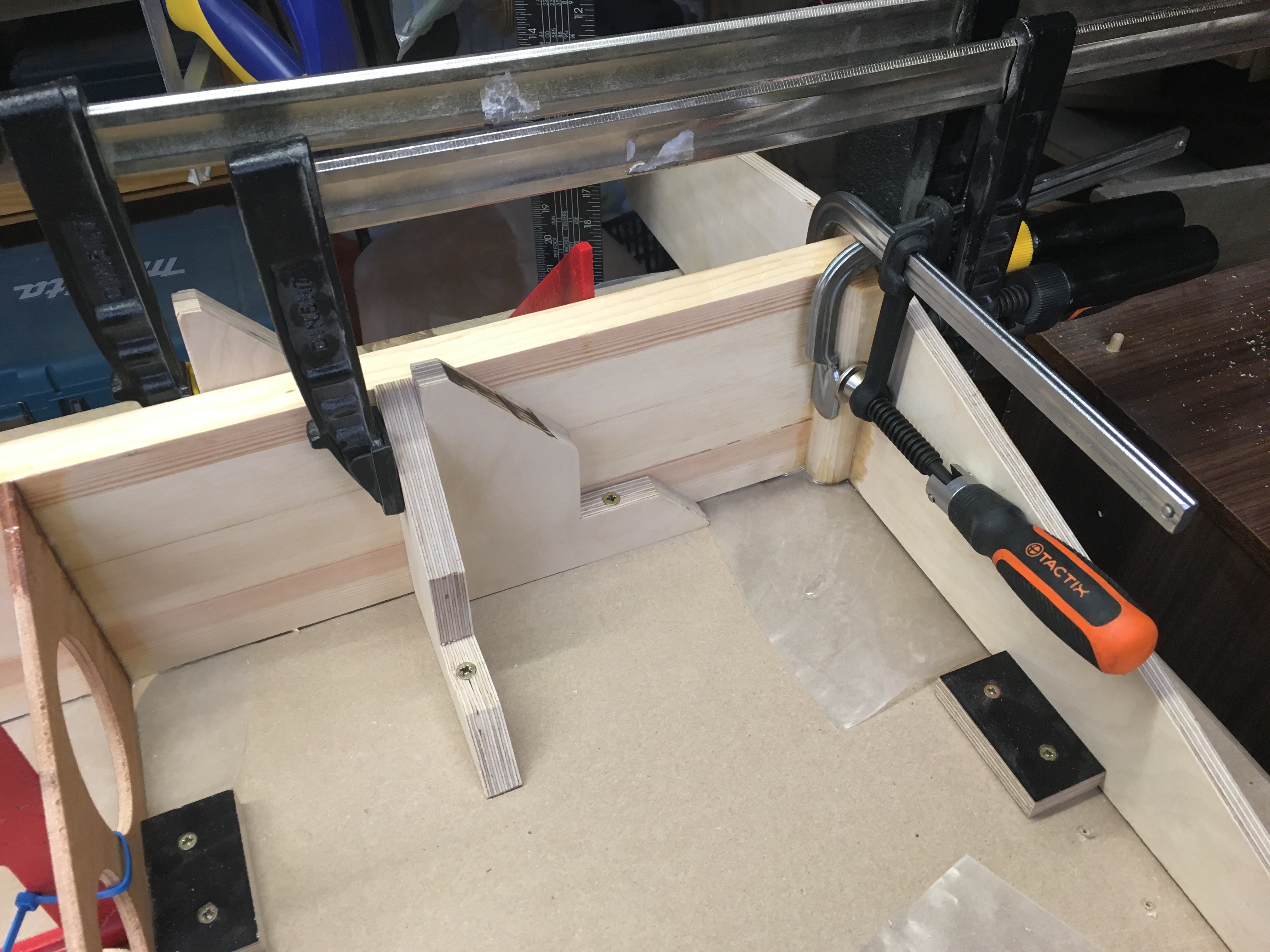

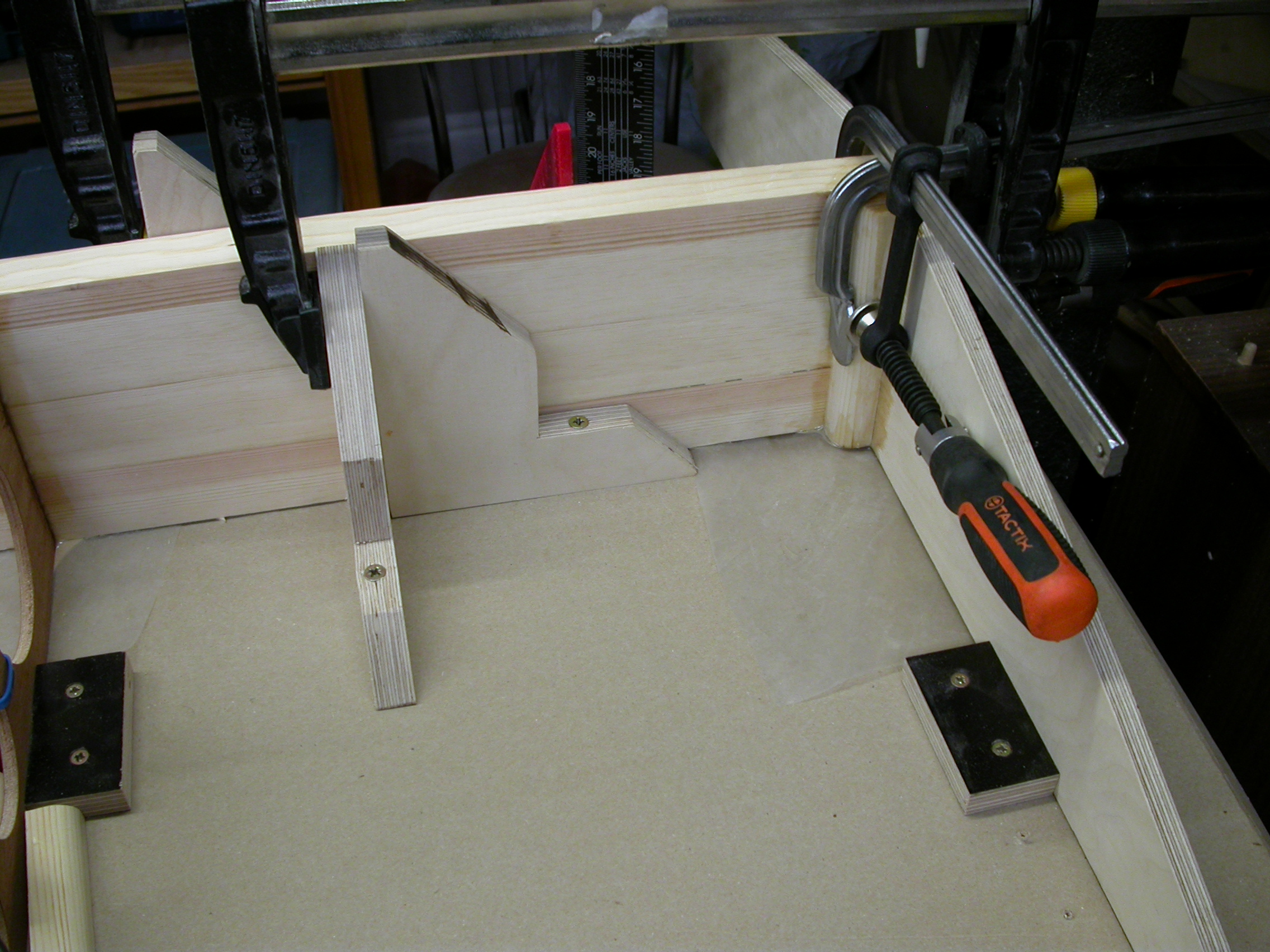

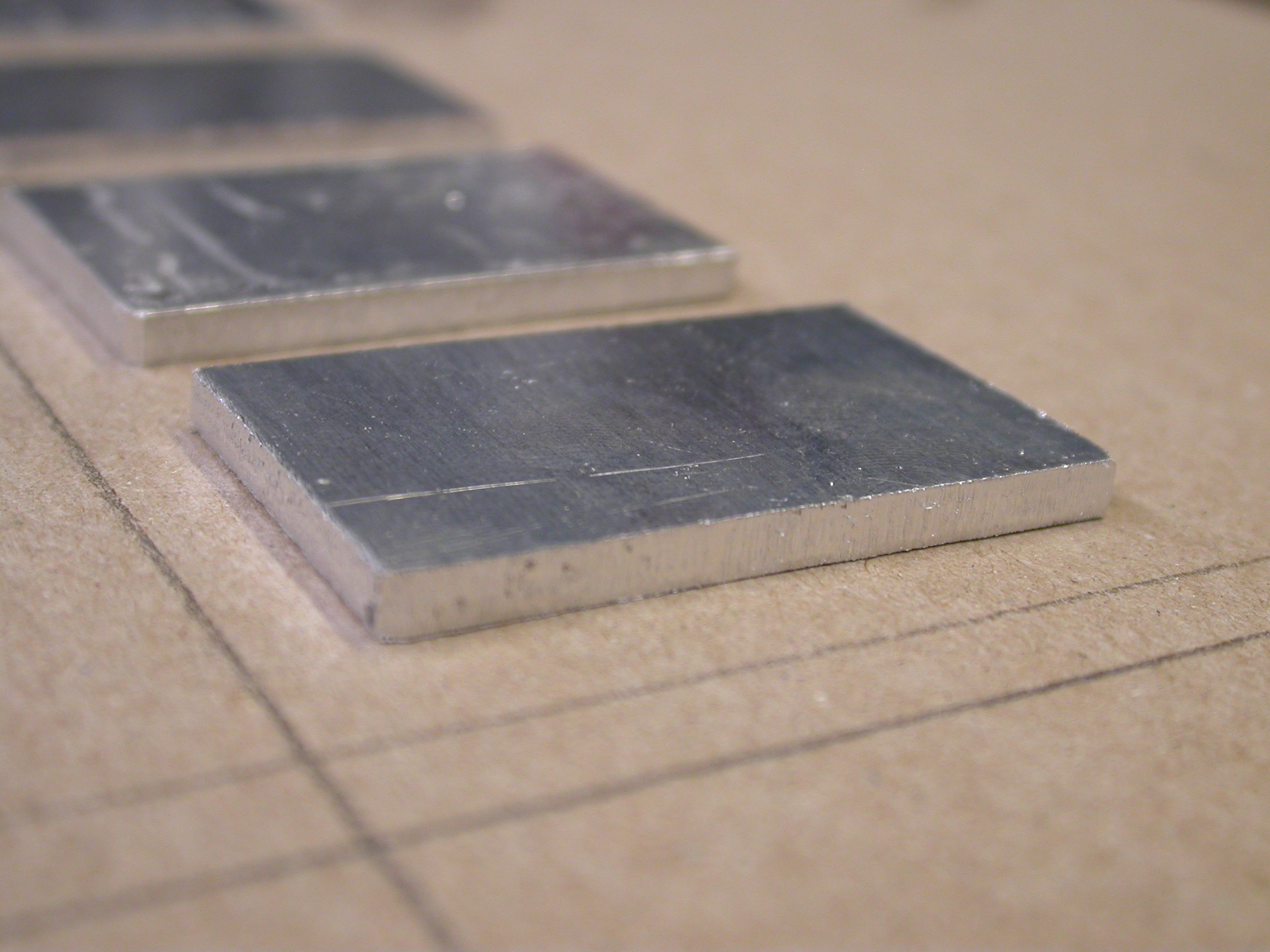

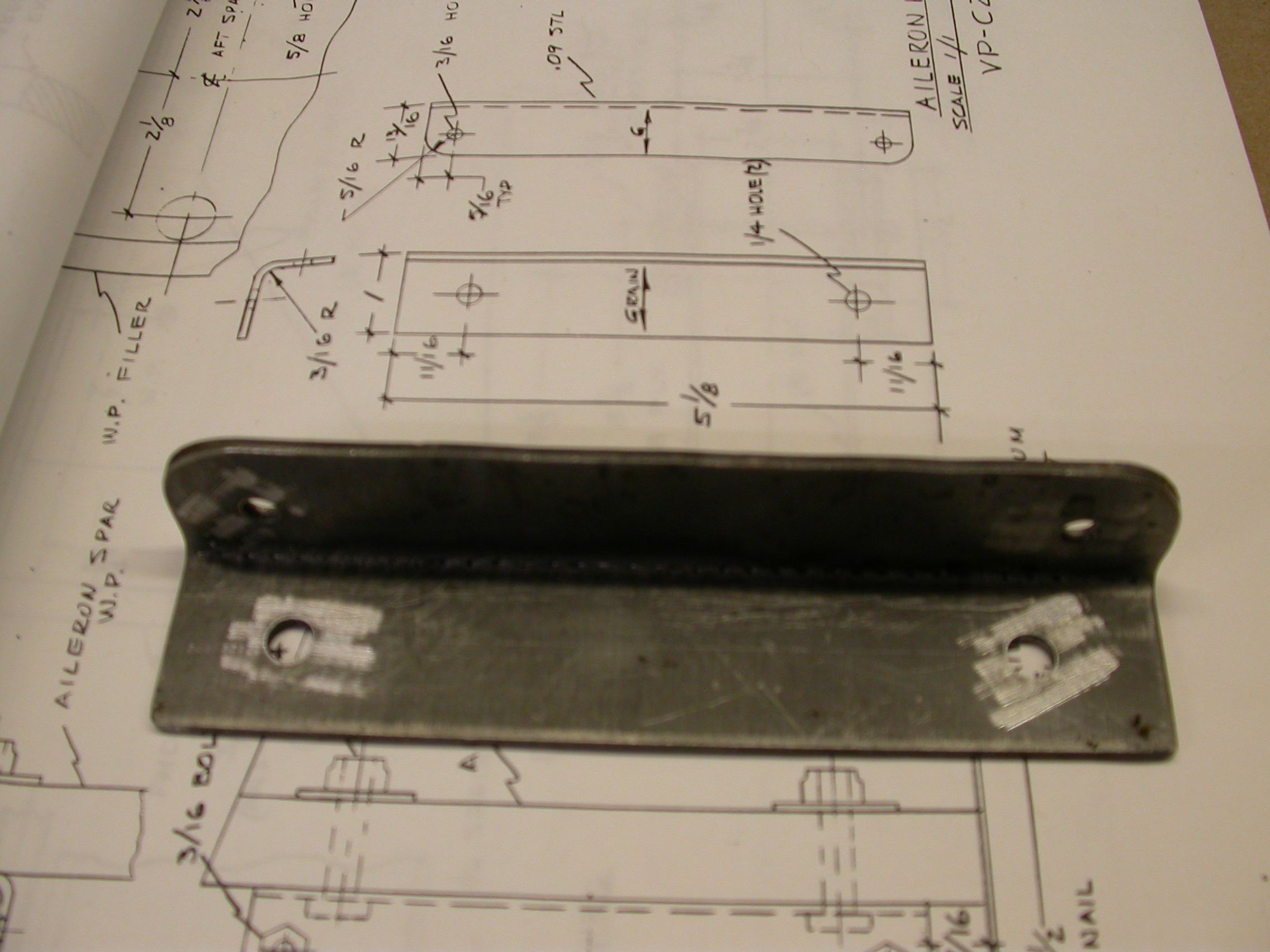

I believe that reasons my first aileron gussets came off were temperature, humidity and too much of cotton flakes. Temperature in my shop was around 16 degrees C and humidity was low, but I am sure there is no sufficient contact area for epoxy to hold as well, so the space between trailing edge and gusset was filled with a piece of white pine wedge. I have done similar technique for the gussets on the trailing edge of the wing.

25 g of fast curing Epoxy L20 was used (EPH 573 hardener). More epoxy was needed to will gaps between pine wedge and gusset.

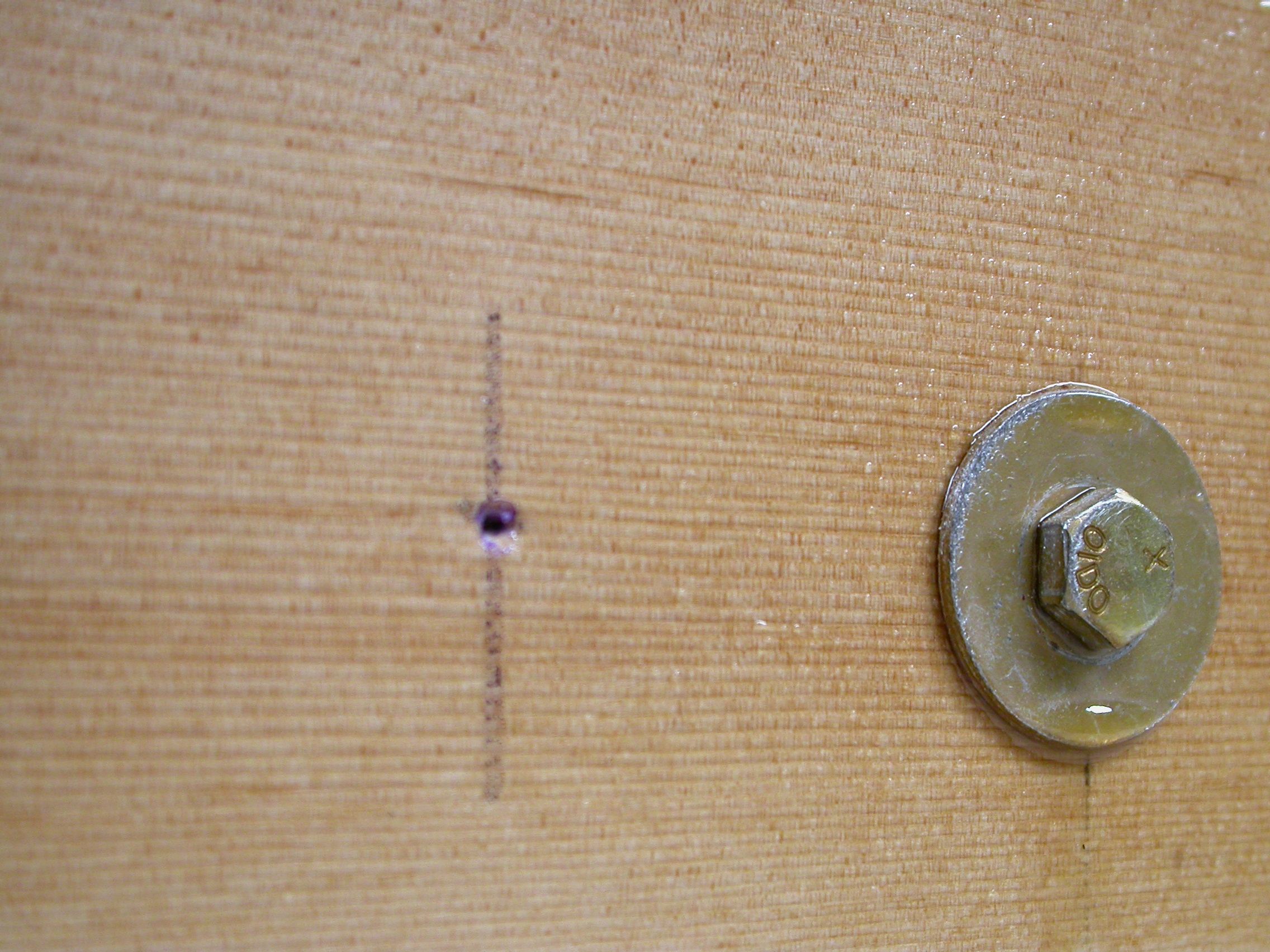

It was a challenge to align eye-bolts.

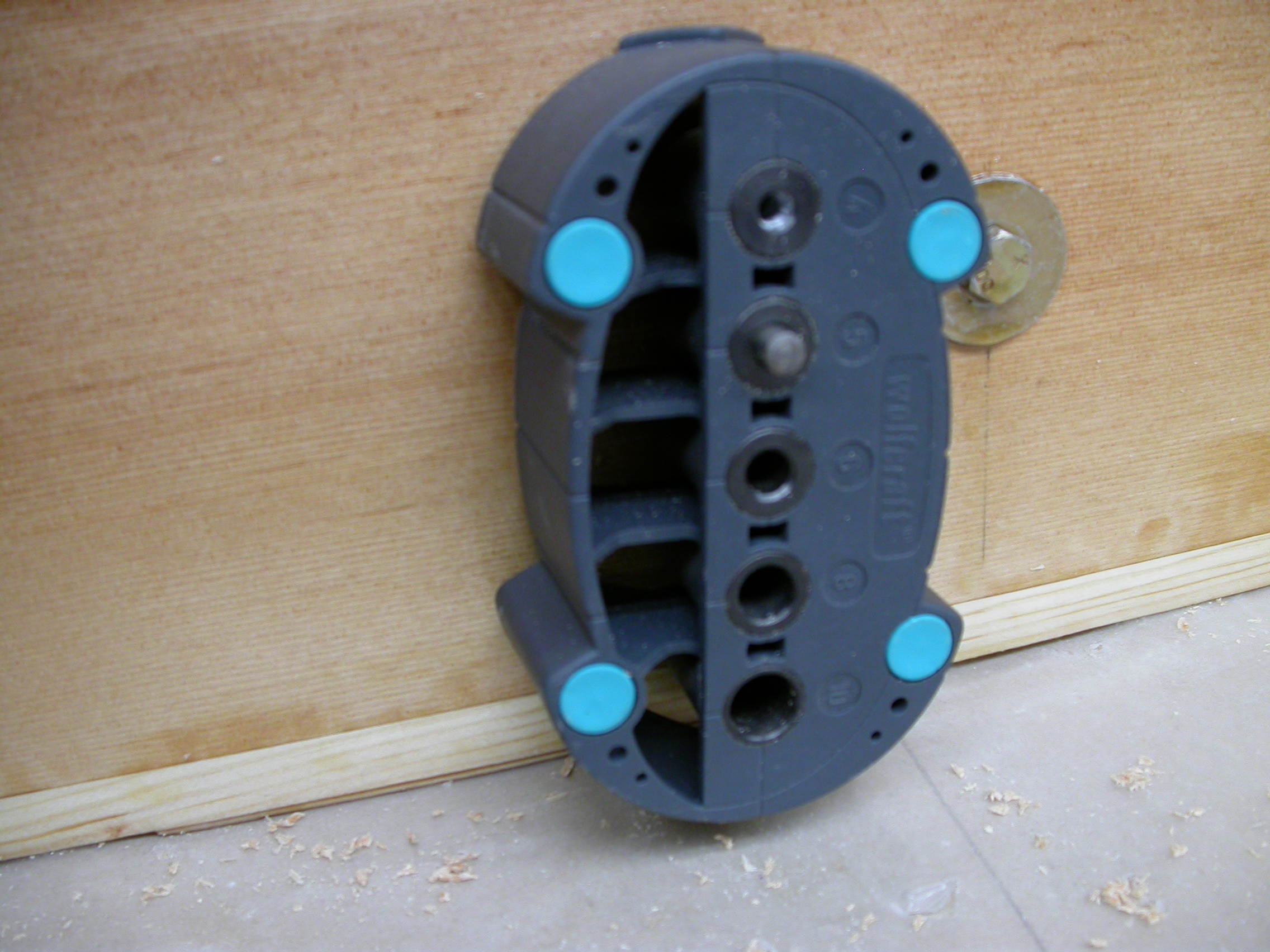

There was a mistake gluing gussets to the trailing edge of the aileron. It is no summer anymore and temperature in my shop is around 15-16 degrees C. with humidity around 40-50%. L20 Epoxy in the summer has to be mixed according to the mixing table and left alone for 1 hour (that’s different temperature and humidity in summer). Then is has to be applied and left to soak for 15’. During this time cotton wool flakes has to be mixed into the epoxy. The mistake was, that I took too much cotton flakes (it has to be one teaspoon to 100 g of mixture) and I did not accounted for the low humidity and low temperature in my shop.

Next morning my gussets came off with gentle pull. You can see this in the pictures. Today I have made a “green house” with electric heater for my aileron and properly mixed epoxy with cotton flakes.

In general, it takes 70 g of Epoxy mixture to glue all the aileron’s gussets