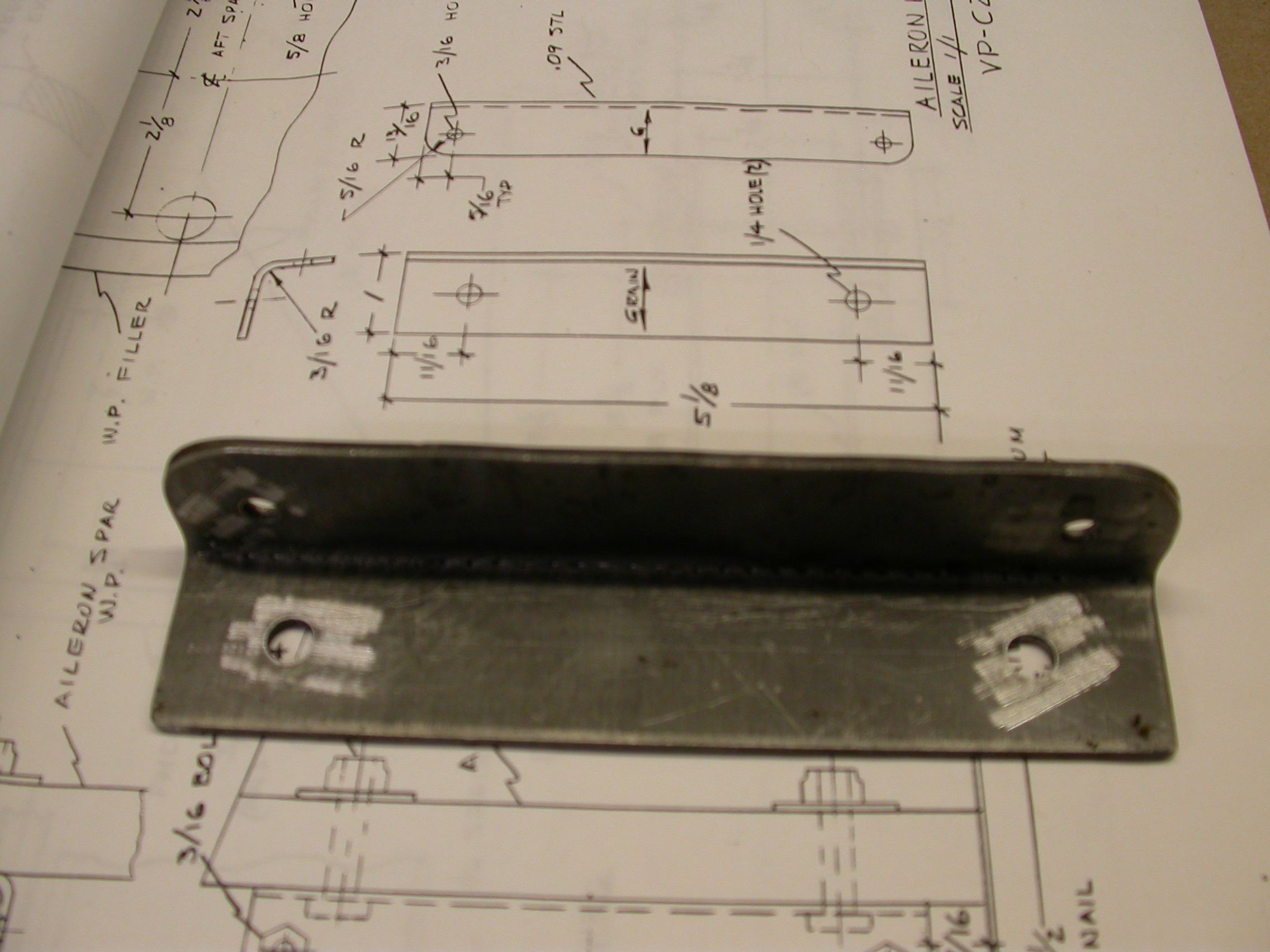

I believe that reasons my first aileron gussets came off were temperature, humidity and too much of cotton flakes. Temperature in my shop was around 16 degrees C and humidity was low, but I am sure there is no sufficient contact area for epoxy to hold as well, so the space between trailing edge and gusset was filled with a piece of white pine wedge. I have done similar technique for the gussets on the trailing edge of the wing.

25 g of fast curing Epoxy L20 was used (EPH 573 hardener). More epoxy was needed to will gaps between pine wedge and gusset.

It was a challenge to align eye-bolts.